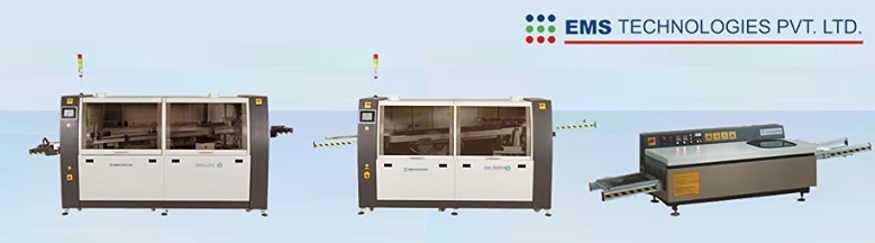

- Lead Free Wave Soldering Machine

We offer right from Low Volume Production Table Top Lead Free Wave Solder to High Volume fully computerized Lead Free Wave Solder Machines. Pallet less conveyor design, Titanium Solder Pot, Spray Fluxer & much more

Stallion μ321 fc

Finger conveyor

Finger conveyor

◦PLC controlled with touch screen operation

◦Profile storage for 999 PCBs in USB drive

◦Management data , Password protected

◦RS 485 Interface for Upgradation

◦Full Titanium Finger conveyor with adjustable width from 70 mm to 300mm

◦4, 5, & 6 Degrees adjustable conveyor angle

◦Standard- Foam fluxer

◦Option- Spray fluxer

◦2 Stage pre-heating of hot air convection pre-heater ( Three stage pre heating optional)

◦Specially coated solder pot suitable for Lead-free or Titanium solder- pot option

◦O-Wave option for SMD soldering ( Optional Dual wave )

◦Cooling fan at the exit

◦PID control for pre-heaters and solder pot

◦Roll out solder pot for ease of maintenance

◦Exchange solder pot can be provided as option

◦Highly reliable AC motors with in-built speed control for stable wave height, SMD

O-Wave and conveyor speed

◦18 kW power consumption

◦Automatic Finger cleaning system

◦Profile storage for 999 PCBs in USB drive

◦Management data , Password protected

◦RS 485 Interface for Upgradation

◦Full Titanium Finger conveyor with adjustable width from 70 mm to 300mm

◦4, 5, & 6 Degrees adjustable conveyor angle

◦Standard- Foam fluxer

◦Option- Spray fluxer

◦2 Stage pre-heating of hot air convection pre-heater ( Three stage pre heating optional)

◦Specially coated solder pot suitable for Lead-free or Titanium solder- pot option

◦O-Wave option for SMD soldering ( Optional Dual wave )

◦Cooling fan at the exit

◦PID control for pre-heaters and solder pot

◦Roll out solder pot for ease of maintenance

◦Exchange solder pot can be provided as option

◦Highly reliable AC motors with in-built speed control for stable wave height, SMD

O-Wave and conveyor speed

◦18 kW power consumption

◦Automatic Finger cleaning system

◦PLC Controlled with Touch screen panel

◦Profile storage for 999 PCBs with USB drive

◦Management data, Password protected

◦RS 485 Interface

◦Pallet (carrier) type conveyor for max. PCB width 300 mm

◦3, 4, & 5 Degrees adjustable conveyor angle

◦2 Stage pre-heating combination of hot air convection pre-heater or IR pre- heaters

◦Specially coated solder pot suitable for Lead-free or Titanium solder- pot option

◦O-Wave option for SMD soldering, ( Optional Dual wave )

◦Cooling fan at the exit

◦PID control for pre-heaters and solder pot

◦N2 Curtain option

◦Roll out solder pot for ease of maintenance

◦Exchange solder pot available as option

◦Highly reliable AC motors with in-built speed control for stable wave height, SMD O-Wave and conveyor speed

◦12 kW power consumption

◦Profile storage for 999 PCBs with USB drive

◦Management data, Password protected

◦RS 485 Interface

◦Pallet (carrier) type conveyor for max. PCB width 300 mm

◦3, 4, & 5 Degrees adjustable conveyor angle

◦2 Stage pre-heating combination of hot air convection pre-heater or IR pre- heaters

◦Specially coated solder pot suitable for Lead-free or Titanium solder- pot option

◦O-Wave option for SMD soldering, ( Optional Dual wave )

◦Cooling fan at the exit

◦PID control for pre-heaters and solder pot

◦N2 Curtain option

◦Roll out solder pot for ease of maintenance

◦Exchange solder pot available as option

◦Highly reliable AC motors with in-built speed control for stable wave height, SMD O-Wave and conveyor speed

◦12 kW power consumption

Stallion μ321 cc

Carrier Type

Carrier Type

Table Top

Stallion mctt

Stallion mctt

◦Field proven model with over 250 installations

◦Power saving model with 6 Kw power consumption

◦170 Kg solder pot

◦Pallet (Carrier) type conveyor for max PCB width 300mm

◦3, 4, & 5 degree adjustable conveyor angles

◦Foam fluxer

◦High-efficiency IR pre-heater

◦'O-Wave' option for SMD soldering

◦PID Control for pre-heaters and solder pot

◦Highly reliable AC motors with in-built speed control for stable wave height, SMD O-Wave and conveyor speed

◦Auto WaveON and Weekly/Daily Timer

◦Auto Flux Density Controller option

◦Power saving model with 6 Kw power consumption

◦170 Kg solder pot

◦Pallet (Carrier) type conveyor for max PCB width 300mm

◦3, 4, & 5 degree adjustable conveyor angles

◦Foam fluxer

◦High-efficiency IR pre-heater

◦'O-Wave' option for SMD soldering

◦PID Control for pre-heaters and solder pot

◦Highly reliable AC motors with in-built speed control for stable wave height, SMD O-Wave and conveyor speed

◦Auto WaveON and Weekly/Daily Timer

◦Auto Flux Density Controller option