Accurate - IPC Compliant - Relevant

Today's Zero Ion is designed to meet the cleanliness testing challenges associated with modern circuit assemblies. The Zero Ion is capable of extracting and quantifying assembly contamination levels per IPC J STD001 TM 2.3.25 and other military specifications.

When Cleanliness Matters - Accuracy Matters

The Zero Ion utilizes Dynamic Measurement Technology which increases the accuracy of the test by maintaining test fluid sensitivity throughout the testing process. The Zero Ion was determined to be the most sensitive tester available by the US Navy. Because any cleanliness tester can only quantify contamination it extracts from an assembly, the Zero Ion utilizes an effective cross-flow extraction process, subjecting the circuit assembly to rapid fluid currents, assisting in the extraction, solubilization, and quantification of assembly residues.

Ambient Temperature Testing

The Zero Ion performs accurate cleanliness testing without needing to heat the test solution. Ambient temperature cleanliness testing eliminates the need for heaters, eliminating warm-up times while increasing equipment and operator safety. The Zero Ion's proprietary extraction process and dynamic measurement technology provide high levels of accuracy without the need for heat.

Today's Zero Ion is designed to meet the cleanliness testing challenges associated with modern circuit assemblies. The Zero Ion is capable of extracting and quantifying assembly contamination levels per IPC J STD001 TM 2.3.25 and other military specifications.

When Cleanliness Matters - Accuracy Matters

The Zero Ion utilizes Dynamic Measurement Technology which increases the accuracy of the test by maintaining test fluid sensitivity throughout the testing process. The Zero Ion was determined to be the most sensitive tester available by the US Navy. Because any cleanliness tester can only quantify contamination it extracts from an assembly, the Zero Ion utilizes an effective cross-flow extraction process, subjecting the circuit assembly to rapid fluid currents, assisting in the extraction, solubilization, and quantification of assembly residues.

Ambient Temperature Testing

The Zero Ion performs accurate cleanliness testing without needing to heat the test solution. Ambient temperature cleanliness testing eliminates the need for heaters, eliminating warm-up times while increasing equipment and operator safety. The Zero Ion's proprietary extraction process and dynamic measurement technology provide high levels of accuracy without the need for heat.

Zero Ion

Ionic Contamination (Cleanliness) Tester

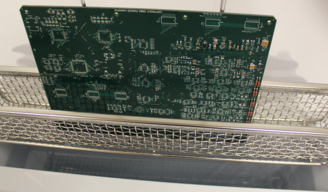

With today's high board densities, and fine-pitch surface-mount devices, in an era of ISO and other quality standards, the requirements for accurate contamination (cleanliness) testing are high.

Ionic contamination testers were designed and implemented for the purpose of determining and monitoring the cleanliness of assemblies. Resistivity of Solvent Extract (ROSE) testers are utilized to ensure that cleaning processes remain within tolerance of IPC and MIL specifications. The Zero-Ion G3 ionic contamination tester meets industrial cleanliness specifications including MIL-STD-2000A, MIL-P-28809 and IPC-001 TM-650 through the use of dynamic measurement technology.

The Zero-Ion tester was selected as the "benchmark" unit for the 1993 study "An In-Depth Look at Ionic Contamination Testing" conducted by the Electronics Manufacturing Production Facility (EMPF), Navy National Center of Excellence for Electronics Manufacturing.

This system provides quick and precise cleanliness measurements of printed circuit assemblies, bare boards, and other electro-mechanical devices. Its ease of use and dynamic results in all three of the leading ionic tester equivalency formats, make the Zero-Ion tester the choice of electronics manufacturers all over the world.

The unit's Windows PC based control system provides an operator friendly interface and captures all relevant testing data. The PC based control system automatically calculates NaCl/square equivalence (per military and IPC specifications), operates in automatic and manual modes, and is equipped with virtually limitless test recipe capabilities. The combination of test board submersion and immersion spraying creates an environment whereby all of the soluble contamination is extracted and measured.

Specifications:

Zero Ion G3-12:

12" x 12" Board Capacity

304mm x 304mm

Zero Ion G3-18:

18" x 18" Board Capacity

457mm x 457mm

Zero Ion G3-24:

24" x 24" Board Capacity

609mm x 609mm

Zero Ion G3-CUS:

Custom sizes available

Features:

Ionic Contamination (Cleanliness) Tester

With today's high board densities, and fine-pitch surface-mount devices, in an era of ISO and other quality standards, the requirements for accurate contamination (cleanliness) testing are high.

Ionic contamination testers were designed and implemented for the purpose of determining and monitoring the cleanliness of assemblies. Resistivity of Solvent Extract (ROSE) testers are utilized to ensure that cleaning processes remain within tolerance of IPC and MIL specifications. The Zero-Ion G3 ionic contamination tester meets industrial cleanliness specifications including MIL-STD-2000A, MIL-P-28809 and IPC-001 TM-650 through the use of dynamic measurement technology.

The Zero-Ion tester was selected as the "benchmark" unit for the 1993 study "An In-Depth Look at Ionic Contamination Testing" conducted by the Electronics Manufacturing Production Facility (EMPF), Navy National Center of Excellence for Electronics Manufacturing.

This system provides quick and precise cleanliness measurements of printed circuit assemblies, bare boards, and other electro-mechanical devices. Its ease of use and dynamic results in all three of the leading ionic tester equivalency formats, make the Zero-Ion tester the choice of electronics manufacturers all over the world.

The unit's Windows PC based control system provides an operator friendly interface and captures all relevant testing data. The PC based control system automatically calculates NaCl/square equivalence (per military and IPC specifications), operates in automatic and manual modes, and is equipped with virtually limitless test recipe capabilities. The combination of test board submersion and immersion spraying creates an environment whereby all of the soluble contamination is extracted and measured.

Specifications:

Zero Ion G3-12:

12" x 12" Board Capacity

304mm x 304mm

Zero Ion G3-18:

18" x 18" Board Capacity

457mm x 457mm

Zero Ion G3-24:

24" x 24" Board Capacity

609mm x 609mm

Zero Ion G3-CUS:

Custom sizes available

Features:

- Dimensions 28" x 53 1/4" x 53"

- Weight 288 lbs

- Electrical Requirements (North America): 120VAC, 10 Amps

- Electrical Requirements (Export): 230 VAC, 1 Phase, 5 Amps,

- Test Method: Dynamic

- Control System: All-in-One PC

- Graphic User Interface / LCD Screen

- Counter Top: ESD Safe Laminate with ESD Ground Plug

- Test Solution 75% IPA / 25%

- Test Result Display: On Screen, PDF Report Writer, Excel Export