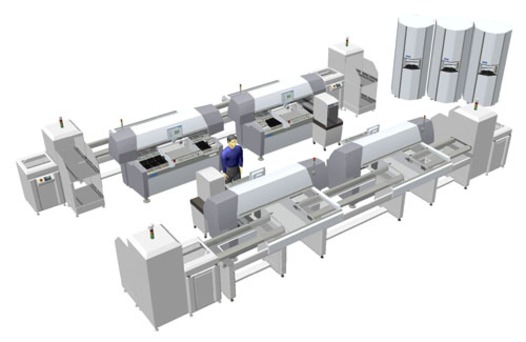

Production lines

Placement equipment

Component feeders

Jet printing equipment

Component storage

Software

Board Handling

Placement equipment

Component feeders

Jet printing equipment

Component storage

Software

Board Handling

The large capacity solution for continuous high-mix production

Speed and efficiency

Combine two MY200HX/MY200DX lines in a single workcell, and you have a full 180,000 cph placement capacity at your control – enabling a single operator to maintain continuous production. Best of all, the same equipment can build your prototypes as well, with a minimum of impact on your overall efficiency.

Seamless transitions

Old school electronics manufacturing stated that the prototype line and the high-volume line were bound to incorporate different machines, different software and different feeders. The transition from one to another was tellingly known as "throwing the design over the fence". Those days are officially over. A new era of seamless transitions between NPI and volume production has begun with the introduction of the MY200 series.

Single-vendor saves time and cost

Imagine having a high-volume line with all the flexibility that Mycronic is known for. Imagine going from prototype to volume with no re-programming, no re-tooling and no hassle of setting up new vision camera parameters. It's not only possible, with the MY200 series it's the financially sound thing to do. Implementing a single-vendor solution will reduce training and maintenance cost, as well as allowing for a much higher degree of freedom when it comes to staffing and planning issues.

Key benefits

180 000 cph within one work cell

On-the-fly changeovers

Near-production storage and automated replenishment

Electrical verification of resistors, capacitors, diodes and transistors

Full traceability

.

Speed and efficiency

Combine two MY200HX/MY200DX lines in a single workcell, and you have a full 180,000 cph placement capacity at your control – enabling a single operator to maintain continuous production. Best of all, the same equipment can build your prototypes as well, with a minimum of impact on your overall efficiency.

Seamless transitions

Old school electronics manufacturing stated that the prototype line and the high-volume line were bound to incorporate different machines, different software and different feeders. The transition from one to another was tellingly known as "throwing the design over the fence". Those days are officially over. A new era of seamless transitions between NPI and volume production has begun with the introduction of the MY200 series.

Single-vendor saves time and cost

Imagine having a high-volume line with all the flexibility that Mycronic is known for. Imagine going from prototype to volume with no re-programming, no re-tooling and no hassle of setting up new vision camera parameters. It's not only possible, with the MY200 series it's the financially sound thing to do. Implementing a single-vendor solution will reduce training and maintenance cost, as well as allowing for a much higher degree of freedom when it comes to staffing and planning issues.

Key benefits

180 000 cph within one work cell

On-the-fly changeovers

Near-production storage and automated replenishment

Electrical verification of resistors, capacitors, diodes and transistors

Full traceability

.