Production lines

Placement equipment

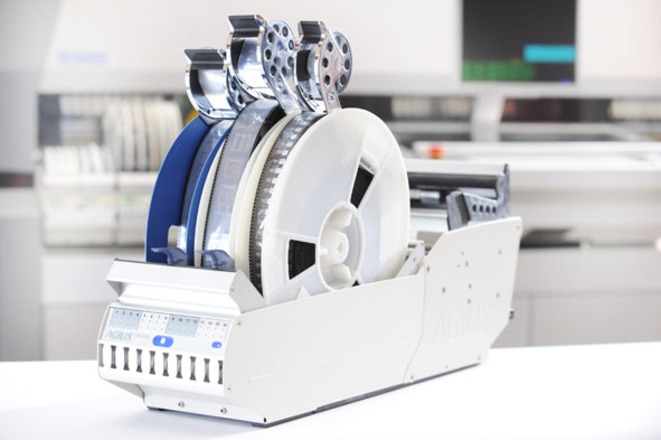

Component feeders

Jet printing equipment

Component storage

Software

Board Handling

Placement equipment

Component feeders

Jet printing equipment

Component storage

Software

Board Handling

Do you recognize any of these challenges?

Last-minute customer requests. Increasingly complex boards. Stock accuracy and inventory issues. And more and more changeovers – at all throughput levels. If you nodded to any of the above, you are not alone. Yet to be successful in today’s SMT business, you need to be able to handle it all – from increasingly shorter batch sizes and board complexity to a wide variety of components. Success requires a fully integrated approach – one in which software and logistics are unified. It’s something Mycronic has been doing for years. Now we are seeing the need at all levels of production. With the MY200 pick-and-place series, we’ve combined the advantages of our high-mix thinking into a flexible, fully integrated solution that works at virtually any volume.

A platform for the future

The MY200-series contains new and advanced technologies, that give our customers higher throughput, higher accuracy and improved line utilization. The major improvements on the new machine series include a new high-performance component inspection and positioning system – Linescan Vision System 3, and a new high-speed mount head for highly accurate placement of the latest component technologies – HYDRA 4.

Boost speed with new linescan camera

The new vision system gives a positive impact on production by including our most advanced vision technologies into one unit. The LVS3 combines the advanced programmable illumination of the Dual Vision System with the well-known image quality and speed of our state-of-the-art linescan camera. This powerful combination vastly improves capabilities for high-speed, on-the-fly inspection and alignment of complex components. The result is a boosting of line speed since a wider array of component types can run in high-speed mode.

Doubling of accuracy with new mount head

In addition to the vision system, the new MY200 machines are equipped with a new HYDRA 4 mount head that is twice as accurate as the previous HYDRA mount heads. Due to improvements both in mechanical design and software processing, the machine can offer high-speed placement repeatability of less than 30 μm at 3-sigma. It means that MY200 users will be getting a higher throughput, so they can run at full speed with high precision and no risk of errors.

A solution for every production scenario

Versatile and easily upgradeable, the new MY200 range includes the following models:

Last-minute customer requests. Increasingly complex boards. Stock accuracy and inventory issues. And more and more changeovers – at all throughput levels. If you nodded to any of the above, you are not alone. Yet to be successful in today’s SMT business, you need to be able to handle it all – from increasingly shorter batch sizes and board complexity to a wide variety of components. Success requires a fully integrated approach – one in which software and logistics are unified. It’s something Mycronic has been doing for years. Now we are seeing the need at all levels of production. With the MY200 pick-and-place series, we’ve combined the advantages of our high-mix thinking into a flexible, fully integrated solution that works at virtually any volume.

A platform for the future

The MY200-series contains new and advanced technologies, that give our customers higher throughput, higher accuracy and improved line utilization. The major improvements on the new machine series include a new high-performance component inspection and positioning system – Linescan Vision System 3, and a new high-speed mount head for highly accurate placement of the latest component technologies – HYDRA 4.

Boost speed with new linescan camera

The new vision system gives a positive impact on production by including our most advanced vision technologies into one unit. The LVS3 combines the advanced programmable illumination of the Dual Vision System with the well-known image quality and speed of our state-of-the-art linescan camera. This powerful combination vastly improves capabilities for high-speed, on-the-fly inspection and alignment of complex components. The result is a boosting of line speed since a wider array of component types can run in high-speed mode.

Doubling of accuracy with new mount head

In addition to the vision system, the new MY200 machines are equipped with a new HYDRA 4 mount head that is twice as accurate as the previous HYDRA mount heads. Due to improvements both in mechanical design and software processing, the machine can offer high-speed placement repeatability of less than 30 μm at 3-sigma. It means that MY200 users will be getting a higher throughput, so they can run at full speed with high precision and no risk of errors.

A solution for every production scenario

Versatile and easily upgradeable, the new MY200 range includes the following models: